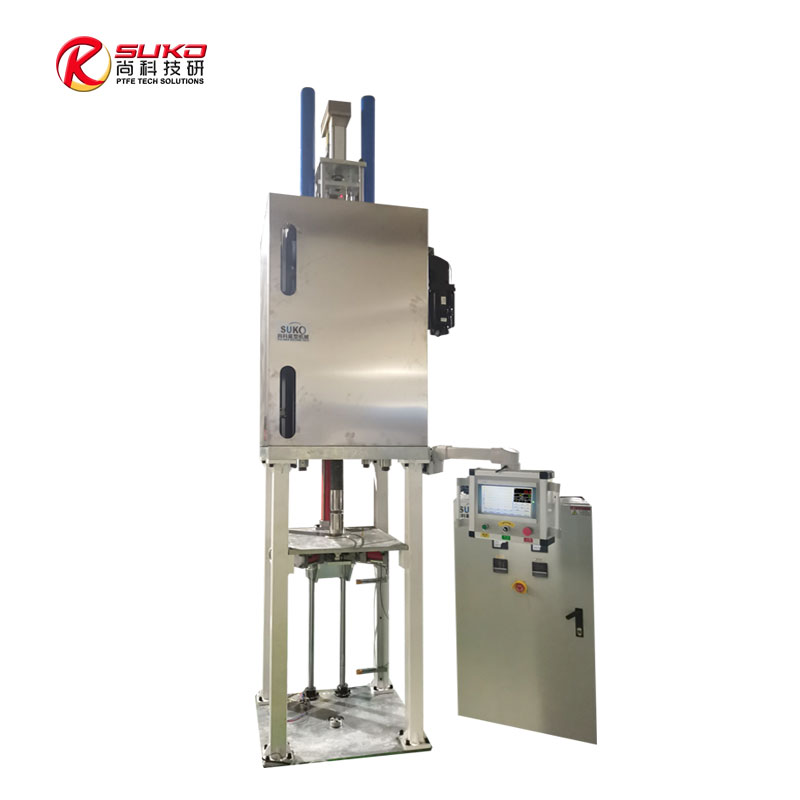

PTFE Hose Paste Extruder Machine

PTFE Hose Paste Extruder Machine

Product Overview

The PTFE Hose Paste Extruder Machine from SUKO is a state-of-the-art PTFE extrusion machine designed for the efficient production of high-quality, chemical-resistant and high-temperature-resistant hoses. As a leading PTFE pipe extruder, this durable PTFE extruder machine ensures reliable, long-term continuous operation, minimizing downtime and material waste. Ideal for industrial applications requiring precision extrusion equipment, it produces hoses capable of withstanding extreme temperatures from -200°C to +260°C. SUKO’s PTFE Hose Paste Extruder Machine combines advanced hydraulic drive technology with high-precision engineering, making it the perfect choice for manufacturing robust PTFE hoses used in demanding environments such as chemical processing, automotive, and aerospace industries.

For more information or to inquire about customization, visit our contact page or email us at info@sukoptfe.com. Explore our full range of PTFE machinery at SUKO PTFE.

Key Features

- High Precision Extrusion: The PTFE Hose Paste Extruder Machine delivers exceptional accuracy in hose production, with tolerances as low as ±0.02mm for outer diameters (OD), ensuring consistent quality in every PTFE pipe extruder output.

- Robust Hydraulic Drive: Equipped with a powerful hydraulic system for smooth, one-key start operation, this PTFE extrusion machine supports continuous extrusion without frequent interruptions, enhancing productivity.

- Minimal Material Waste: Optimized design reduces scrap during the paste extrusion process, making the PTFE extruder machine cost-effective for high-volume manufacturing of PTFE hoses.

- Versatile Temperature Resistance: Produces hoses rated for -200°C to +260°C, ideal for chemical and high-temperature applications.

- Adjustable Speed Control: Features variable speed settings to adapt to different hose pitches, eliminating the need for gear changes and improving operational flexibility.

- Low Noise and High Efficiency: Advanced transmission system ensures quiet operation while maintaining high output rates.

- Easy Installation and Maintenance: User-friendly design with automatic feeding options, simplifying setup and reducing labor costs.

Technical Specifications

The PTFE Hose Paste Extruder Machine is built for reliability and scalability. Below are the core specifications:

| PTFE Hose Paste Extruder Machine | |

| Outside Diameter Range | 0.5-70mm |

| Wall Thickness Range | 0.025mm-2mm |

| Wall Length Range | Depends on pipe size |

| Speed of Production | 0-20m/min |

| Production Type | PTFE lined tubes, thin wall tubes, capillaries, microporous tubes, double layer tubes, multi-lumen tubes, mandrels |

| 1.Preformer | |

| Power | 1-10KW |

| Cylinder Diameter | 30-300mm |

| Length of Loading Chamber | 600-2000mm |

| Extrusion Type | bottom up |

| Pressure Type | hydraulic |

| Voltage | 380V 50HZ 3P |

| 2.Main Extruder | |

| Power | 3-10KW |

| Cylinder Diameter | 30-300mm |

| Loading Chamber Length | 600-2000mm |

| Extrusion Type | Bottom up, top down, horizontal extrusion |

| Pressure Type | Hydraulic, electric cylinders |

| Voltage | 380V 50HZ 3P |

| 3.Sintering Furnace | |

| Power | 2-10kw |

| Height | ≈9000mm |

| Temperature | 500℃ |

| Voltage | 380V 50HZ 3P |

| Number of Furnaces for Sintering | 3 |

These specifications make the PTFE Hose Paste Extruder Machine adaptable to various production scales, from small-batch prototyping to large industrial runs.

Applications

SUKO’s PTFE extrusion machine excels in producing hoses for:

- Chemical processing and transfer lines.

- High-temperature fluid handling in automotive and aerospace.

- Medical and pharmaceutical tubing requiring chemical resistance, including specialized medical hoses for minimally invasive procedures, catheter systems, and biocompatible fluid delivery in healthcare settings.

- Electrical insulation and wire coatings.

- General industrial piping where durability and low friction are essential.

The PTFE pipe extruder supports the creation of unsintered PTFE tapes, thin tubes, and reinforced hoses, ensuring versatility across sectors.

Why Choose SUKO’s PTFE Hose Paste Extruder Machine?

As a trusted manufacturer, SUKO prioritizes innovation in PTFE extruder machine technology. Our machines feature corrosion-resistant components for longevity and integrate seamlessly with sintering ovens, mixing machines, and preform billet systems for a complete production line. With a focus on safety, efficiency, and precision, the PTFE Hose Paste Extruder Machine delivers superior performance, backed by comprehensive after-sales support. Contact us today to discuss how our extrusion equipment can meet your specific needs.